Research

Articles

On the heels of our webinar on achieving higher yields, revenue cycles, and crop quality with light control, we dive into this third and final post of our series on daily light integral (DLI). Earlier in this series, we outlined the basics of optimizing light and identifying target DLI to improve plant health and increase yields year-round.

We usually hear from our commercial partners that after labor costs, energy is their largest expense and concern. Our friends in places like the Kingsville and Leamington areas of Ontario are not only faced with balancing runaway utility expenses (1), but also with predicting if enough electricity (2) will be generated by utility companies’ aging grids to feed their business expansion.

With more automated systems entering greenhouses every year, it’s good to ask how bringing LED light into your operation will result in a net gain. The answer, in part, has to do with DLI.

Give to Get

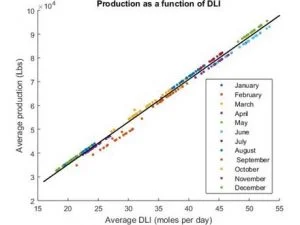

Verified by historical data from commercial growers, and long-supported by the academic research community, there is a 1:1 correlation between DLI and production. As presented by Dr. Ryan Dickson of the University of New Hampshire Cooperative Extension (3) at the 2017 Greenhouse and Production Conference, a 1% increase in DLI correlates to a 1% increase in yield.

Data compiled by a tomato producer in the southwestern United States over two decades showing monthly yields tied directly to the available natural light. No supplemental lighting in use.

Whether leafy greens, tomatoes, or floriculture, increased light intensity (which boosts DLI) up to a saturation point accelerates every stage of plant development. That means cuttings develop robust roots and reach transplant size quickly, which then leaf out on thick, highly branched stems. During rooting (4), maintaining a fixed or stable DLI is important but light intensities should not be high.

By adding just enough light, the University of Akron Research Foundation demonstrated (5) increasing Brix levels (sugars) in hydroponic lettuce. Or in the case of tomatoes, scientists and cultivators are reporting quick-healing grafts, followed by abundant flowers and vigorous fruit sets.

Given increasing consumer demand for fresh produce year-round, a grower’s initial investment in supplemental LED lighting is quickly offset by accelerated harvests, smarter energy consumption, and a uniform, quality yield day in and day out.

The Heliospectra vision is to create a complete biofeedback solution where the plants are in essence controlling the light strategy and control

Real-Time DLI Solutions and Integrated Systems

Using DLI to guide our growth strategies is not a new concept, though how we use it has evolved.

Whereas systems that automatically turn lighting on and off at set times of day were once the vanguard, greater sophistication has given rise to the “hourly response” method. Newer, but still limited, this method uses a data logger that records natural light levels and instructs lights to turn on or remain off on an hourly basis (high-pressure sodium ballasts limit increments shorter than that because they require a warm-up and rest period) in order to meet your plants’ DLI requirements.

Today, programmable horticultural LED grow lights can address changes in natural light conditions in real-time, delivering precise amounts of supplemental light to meet DLI requirements. Whether using energy-efficient LED grow lights for commercial or traditionally energy-hungry HPS for supplemental lighting, further savings can be achieved by shifting run times to off-peak hours where electricity is available at a much lower price.

Heliospectra’s standalone helioCORE control system gives users real-time control of the lights (no waiting for ballasts to warm up) and is also ready to integrate with a wide variety of facility and building control systems.

With the stunning diversity of plants and food grown in greenhouses and controlled environments, today’s LED lighting and control solutions deliver long-lasting performance and dollar savings while improving the overall quality of the crops. As intelligent light solutions continue to evolve, it won’t be long before we can rely on plants to tell the lights what to do.

Sources

- http://www.canadianbusinessexecutive.com/blog/energy-infrastructure-costs-drive-ontario-greenhouse-producers-us

- http://www.thepacker.com/shipping-profiles/ontario-greenhouse-produce/ontario-growers-expand-us

- https://ag.umass.edu/sites/ag.umass.edu/files/pdf-doc-ppt/handoutlight_temperature_relative_humidity_1_12_2016.pdf

- http://gpnmag.com/article/managing-light-to-improve-rooting-of-cuttings/

Get in touch with us!

From custom light planning, to tailored quotes, and everything in between,

our team of horticulture experts are always ready to assist.